2023

Model Year: 2022-2023

History: After the first competition we decided to change our robot’s intake because we found that the first intake was too heavy and affected the balance of the robot. This design change proved to be very beneficial in subsequent competitions.

2021

Robot Name: Charon

Model Year: 2021-22

Features: Charon uses mecanum drive, allowing for maneuverability and space efficiency. It has a four-bar linkage system with the intake attached at the end to move cargo up and down. Another feature is retractable odometry, which measures the change in position of the robot during the autonomous period.

History: After the first competition we decided to make Charon narrower to fit through the gap between the barrier and the wall, increasing its flexibility in teleop and autonomous. Charon won the design award.

2019

Robot Name: Bia

Model Year: 2019-20

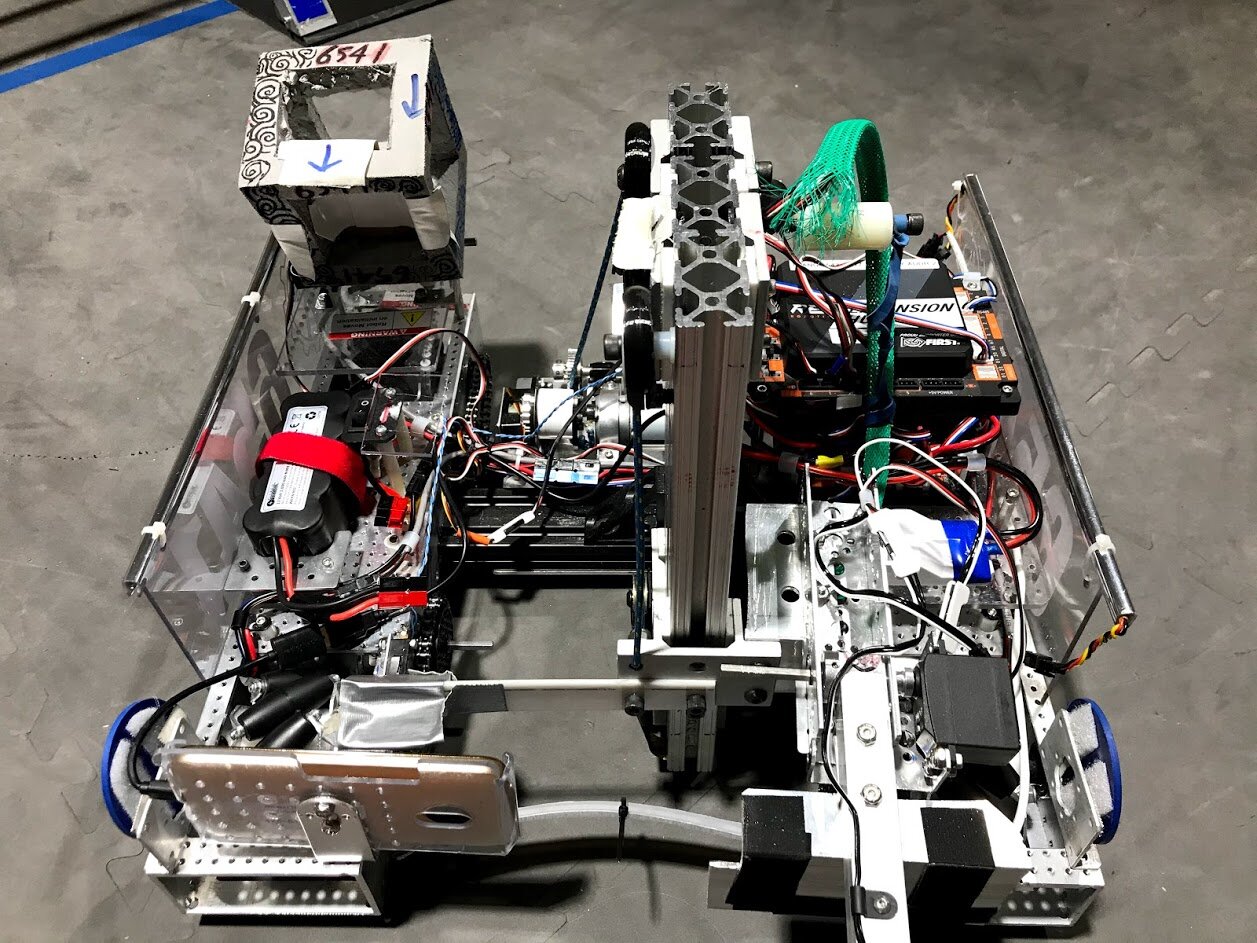

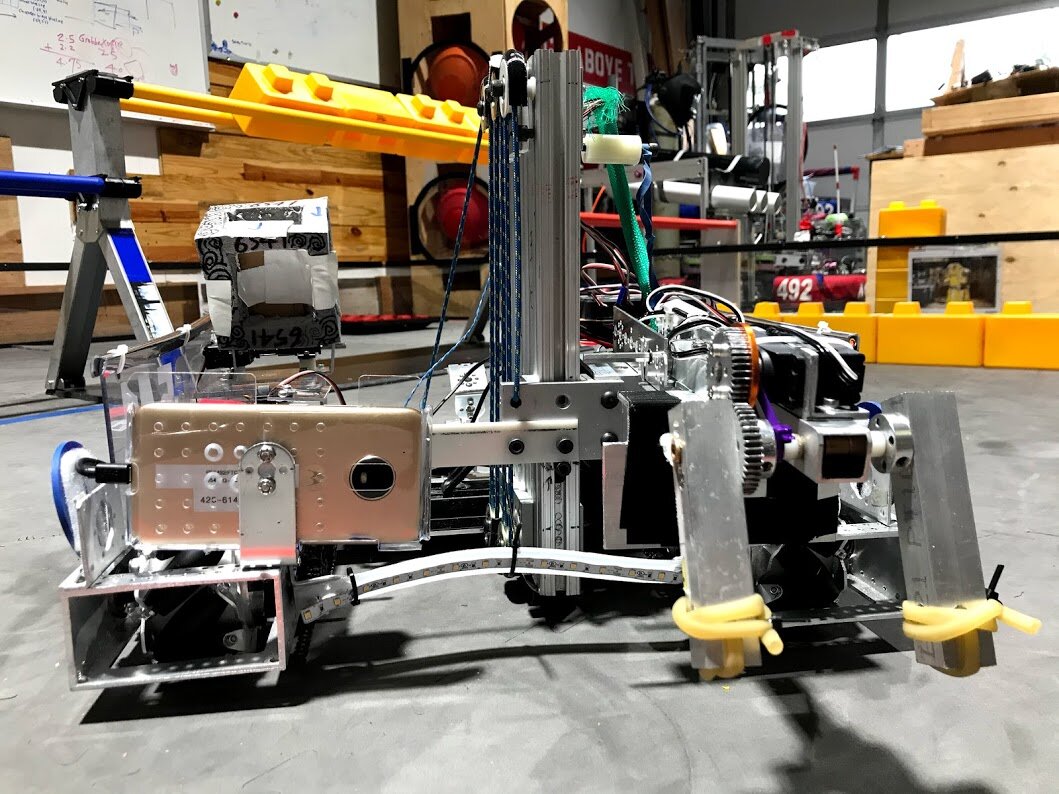

Features: Bia uses an H-frame drive base of two boxes connected with an 80/20 bar, which provides flexibility in mounting mechanisms. The vertical lift end effector works as a hinged claw and moves up/down with an 80/20 bar pulley system. The back of the robot features two grabbers for moving the foundation and a release mechanism to place the capstone.

History: Bia is notable for having an always evolving end effector that changes from competition to competition. Through the season, it changed from a wheel intake to an actual grabber. The software also placed as the runner up for the Control Award.

2017

Robot Name: Atlas

Code Name:

Model Year: 2017-18

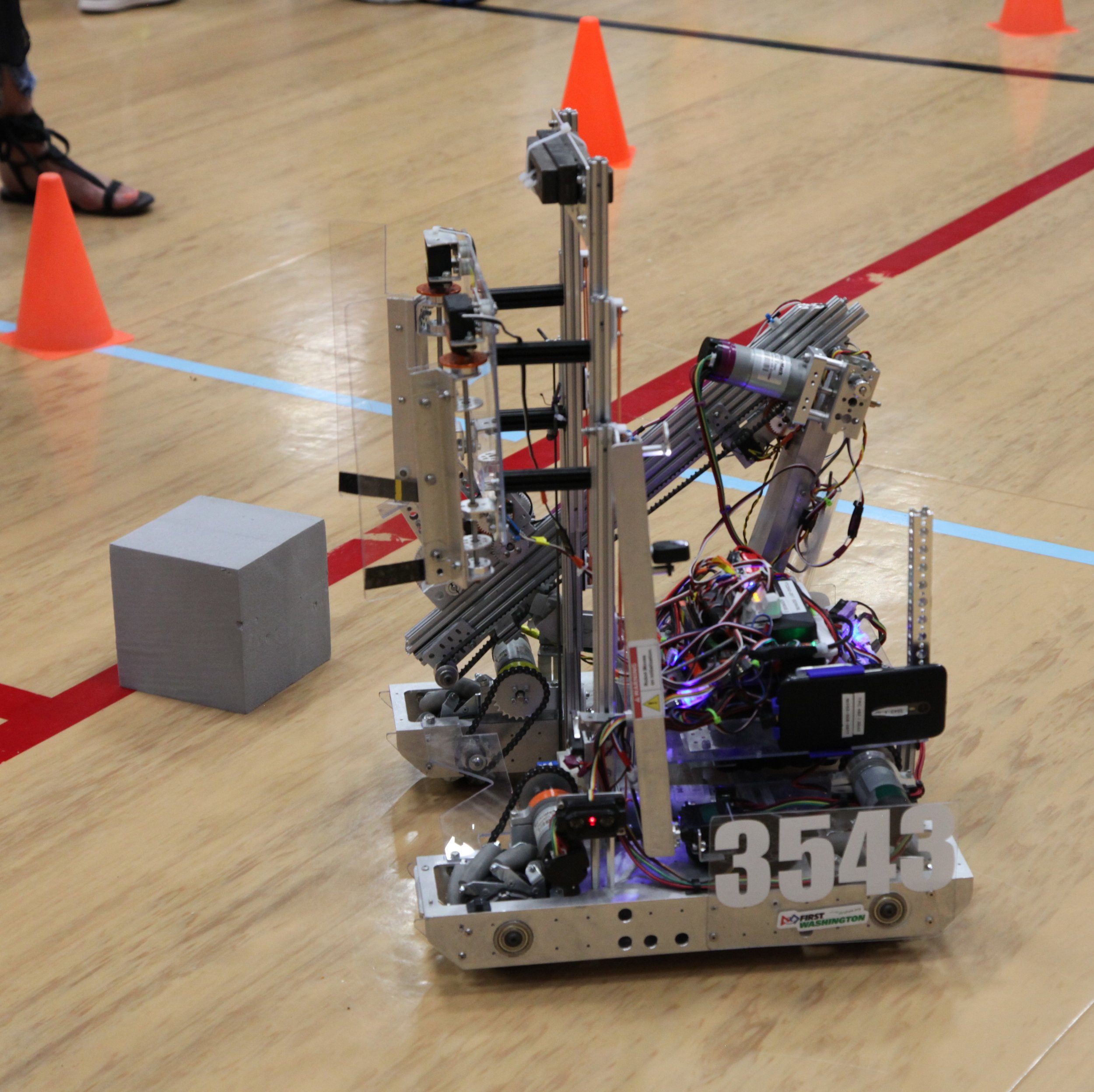

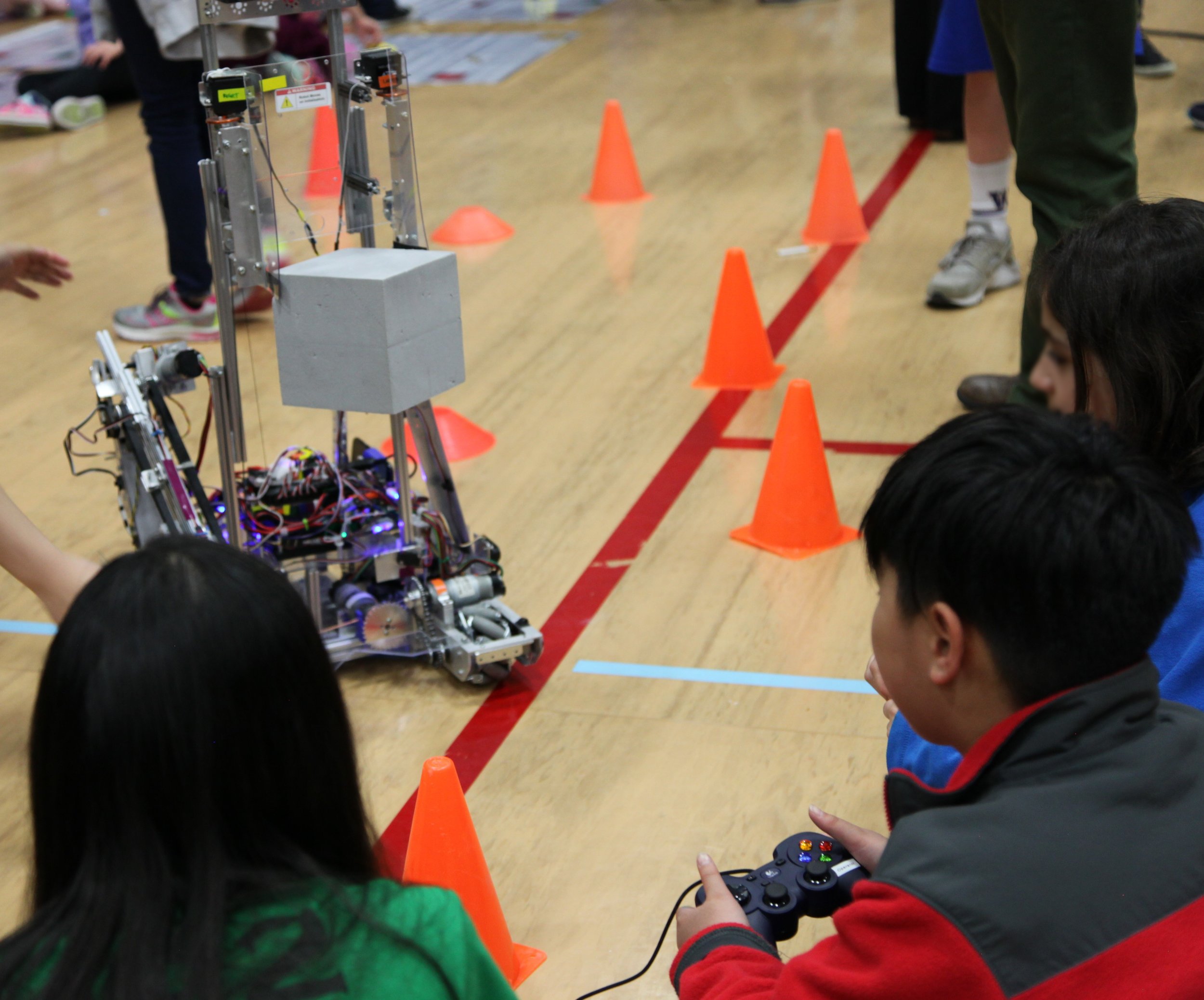

Features: A combined elevator and opposing flaps mechanism that allows the capture and transport of cubes.

History: Despite our loss in competition, Atlas has raised our hearts in outreach by being a reliable robot that has engaged others and inspired us to keep building and improving.

2010

Robot Name: Prometheus

Code Name: Champ

Model Year: 2010-2011

Features: An A-frame design that was chosen to match the shape of the mountain, a mechanism fondly known as “The Flap” that is a simple sheet of poly-carbonate in the front of the robot used to push batons on the ground and to lower the bridge. There is also an arm mechanism with a “wrist” that flips the batons to a vertical position. Batons are picked up through a dispensing mechanism that makes use of LEGO© technology, especially LEGO© treads.

Drivetrain: A chain drive with the chain following the shape of the A-frame. Nothing special about the wheels; they are quite standard and noncommittal.

History: Prometheus’ main problem has always been the chains. In both regional competitions, the chains either fell off or were rubbing against some other object and caused several motors to fry. We hoped that Prometheus would be completely fixed up and not be plagued with Murphy’s Law Syndrome during the Washington State Competition.

Prometheus gave a great effort during the State Championship, as did the team.